About 850 million plastic toothbrushes are directly landfilled every year, 80 billion discarded plastic bottles from shampoo and conditioner alone, and 100 million marine animals die from plastic waste every year.When we have not yet formed a strong awareness of environmental protection, we will only use it as a temporary convenience, causing plastic products to be thrown everywhere and can be seen everywhere, which is closely related to our lives.

As we become more and more aware of the harm of plastics to the environment, and there is no way to completely get rid of plastic products, we will use another way of coexisting in harmony - the recycling of plastic products.

Grandtop recycles, processes and reuses the recycled plastics. The processed plastic fiber is integrated into the product, so the company spends a lot of money to introduce a new energy project - Spunlaced production line. Taking action for environmental protection treatment and resource recycling is in line with the values and brand propositions of a new generation of consumers. We can use this opportunity to get some new inspiration in product planning and innovation.

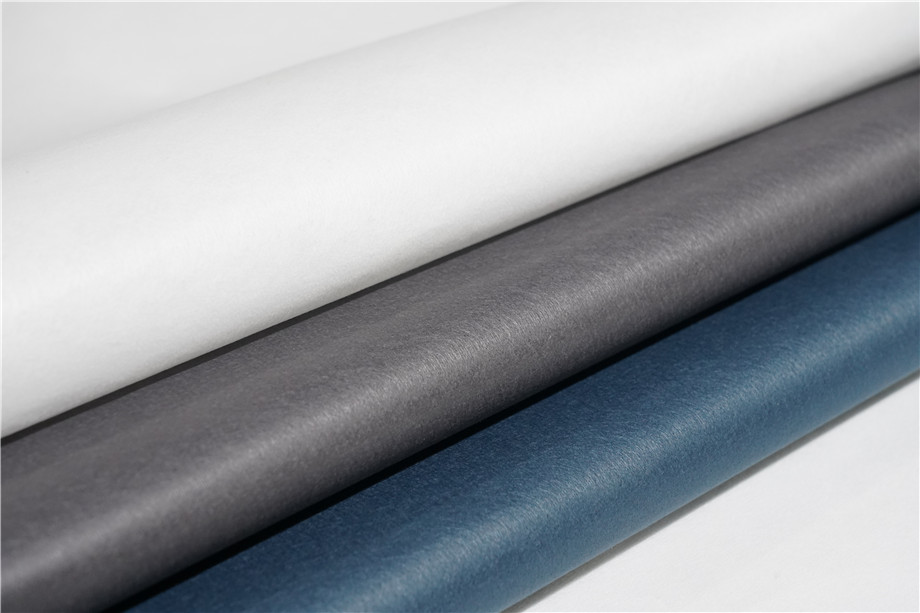

The spunlace production line recycles and reuses discarded plastic products, and uses mature production technology to produce spunlace non-woven products suitable for mass consumption and environmental protection needs. Mainly include spunlace non-woven fabrics, honeycomb fabrics and other derivative products.

As a new resource, RPET plastic bottle flakes that "turn waste into treasure" can not only solve environmental problems, but also realize the sustainable development of resources to a certain extent. RPET regenerated fibers are made into spunlace non-woven fabrics through a special production process. And through the GRS certification, we ensure the safety of product use from the source, and also contribute to the recycling of resources. Spunlace non-woven fabrics are different from traditional fabrics. Instead, the fibers are entangled by high-pressure fine water jets without any chemical binder reinforcement, which greatly reduces environmental pollution.

From raw materials to production, ensure the safety of product production and use, and also contribute to the recycling of resources, and implement the concept of environmental protection from the source.

86-511-88801779

86-511-88801779

Customer service 1

Customer service 1  Customer service 2

Customer service 2